4325 Meyer Rd Fort Wayne, Indiana 46806 | info@ruggedsteelcontainers.com

CALL US TODAY! (260) 444-4241

Unique Features

Common Model Features

AMERI-KAN containers

are some of the most advanced containers on the market. You may ask what makes them so special? Look through the features below and it will become obvious.

Common Model Features

Heavy-Density Polyethylene

AMERI-KAN high-density polyethylene covers are custom-molded with premium quality U.V. stabilizers for flexibility and long life in any climate. The medium black continues to look clean and pleasant with use, is attractively compatible with different container colors and is always comfortable to the touch in the hot sun.

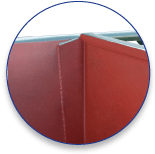

Water Reducible Alkyds

Ameri-kan containers are phosphatized and cleaned prior to applying a corrosion-resistant primer then heat dried. The finish coat is industrial quality enamel, baked on at 320 degrees in your choice of standard green or brown, or other special-order colors.

Clean Dumping

All containers have wrapped corners and floors that are continuously welded inside and skip welded outside. Tapered design allows a clean dump.

Rear Loading Model Features

Superior Pivot Point

Trunnion bars are coupled with double gussets. Model 401 utilizes a 1 1/2 in. solid bar. Models 601 and 801 use structural tube with solid inserts.

Taper-Formed Siderails

Heavy duty side handles, bridge-welded from outside to a plug weld on the inside panel for massive strength where it’s needed most.

201/301 Rear Pickup

A custom fabricated cable pickup hook is standard on Models 201 and 301. The lower formed gusset spreads stress to the extra heavy rear rail.

Unitized Pickup Bar

Heavy duty rear winch pickup bar is unitized within the rear rail and bridged through the bottom of the rear rail to insure maximum strength and durability on Models 401, 401C, 601, and 801.

Front Loading Model Features

Heavy Duty Pockets

Heavy Duty Pockets with the "no step" feature with backer plate. Reinforced pocket guides for fast and dependable fork entry.

CONTACT INFORMATION

- Mon - Fri

- -

- Sat - Sun

- Closed

Available 24/7

OUR LOCATION

BROWSE OUR WEBSITE

CONTACT INFORMATION

- Mon - Fri

- -

- Sat - Sun

- Closed

Available 24/7

OUR LOCATION

HOURS OF OPERATION:

- Mon - Fri

- -

- Sat - Sun

- Closed

Available 24/7

Content, including images, displayed on this website is protected by copyright laws. Downloading, republication, retransmission or reproduction of content on this website is strictly prohibited. Terms of Use

| Privacy Policy